The Importance of Aircon Pressure Tests in Singapore

Your aircon compressor operates within a closed-circuit system, where the refrigerant gas flows continuously. This system is designed to be leak-proof, ensuring efficient cooling performance. However, over time, even the highest quality copper or aluminum pipelines might develop leaks due to wear and tear, poor installation practices, or external damage. When the gas pressure drops, it’s often a sign of a leak—whether minor or major. Understanding the condition of your aircon pipings through a complete pressure test is crucial for maintaining its longevity and efficiency.

Understanding the Cost of a Pressure Test

A complete pressure test isn't a low-cost service, as it is tedious and can take up to 3 days of monitoring to get the full results. It requires specialized equipment and skilled technicians to accurately diagnose the source of the leak. Additionally, the process can be time-consuming, especially if the leak is difficult to locate. However, the benefits of pinpointing the exact issue far outweigh the costs, as it prevents further damage and ensures your aircon resumes peak efficiency.

The Pressure Test Process: How It Works

The goal of a pressure test is twofold: first, to confirm whether there is a leak in your aircon system, and second, to pinpoint exactly where the leak is located. Here's how the process works:

Setup and Monitoring

Monitoring equipment is installed at all the joints within your aircon system. Initial pressure readings are recorded once the setup is complete. These readings serve as a baseline for comparison over the testing period.

Testing Period

The test typically lasts for 2-3 days. The duration depends on the severity of the leak—the larger the leak, the faster the pressure drops. Minor leaks take longer to detect as the drop in pressure is more gradual.

Reading and Analysis

After the testing period, we return to record all the readings again. We analyze the data to identify sections where the pressure has remained constant, which allows us to eliminate those areas as potential sources of the leak.

Final Recommendations

Only after confirming the sections that have lost pressure will we be able to recommend the next steps, which may include targeted repairs or further diagnostics.

Remedy After Identifying the Leak

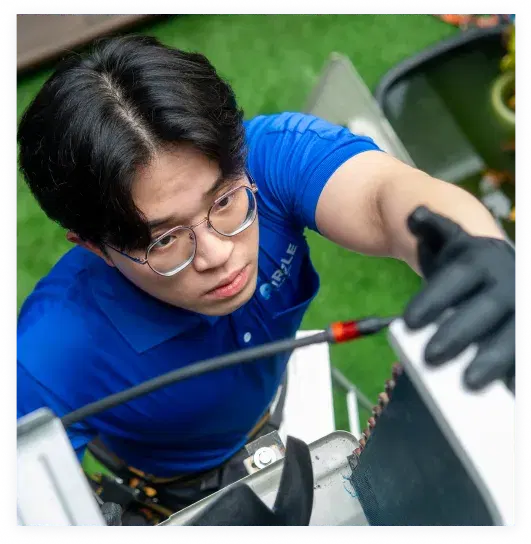

Once the leak has been identified, it’s crucial to determine the exact location to proceed with repairs. The leak could be anywhere—joints, along the refrigerant pipes, and even within the pipes in the condenser or indoor unit coil. After knowing which section of your pipe is leaking, we will zoom in to find the exact leak. Our technicians are equipped with best-in-class gas leak detector tools that can pinpoint the leak's location.

- Accessible Repairs: If the breakage is accessible, such as on an exposed pipe, it can often be repaired easily by welding the affected area.

- Concealed Pipes: However, if the pipes are concealed deep within the masonry wall, pinpointing the exact leak may not be viable. In such cases, we would recommend replacing the entire section of the pipe to ensure a permanent solution.

What You Gain from a Comprehensive Pressure Test

Accurate Diagnosis

Identify the exact location and severity of the leak.

Cost-Efficiency

Avoid repeated costs of gas top-ups by fixing the root problem.

Improved Aircon Performance

Restores your aircon’s cooling efficiency, ensuring a comfortable indoor environment.

Long-Term Savings

Prevents future breakdowns that could lead to costly repairs or replacements.

Customer Success Stories: How Airple Solves Aircon Issues

John's 8-Year-Old Unit

John was experiencing inconsistent cooling in his 8-year-old aircon unit. After a pressure test, we identified a hidden leak in one of the joints. Our team fixed the leak, and John's aircon has been running smoothly ever since. He saved on the cost of a new unit and extended the life of his existing one.

Sarah's Reluctance Turned Confidence

Sarah was hesitant to get a pressure test for her old aircon, fearing it would lead to a costly repair. However, after Airple's technicians conducted the test and explained the process, she felt confident in proceeding. The leak was found and repaired quickly, restoring her aircon's performance and saving her from the expense of a replacement.

Why Choose Airple for Your Aircon Pressure Test?

At Airple, we combine cutting-edge technology with years of expertise to deliver accurate and reliable pressure testing services. Here’s why our customers choose us:

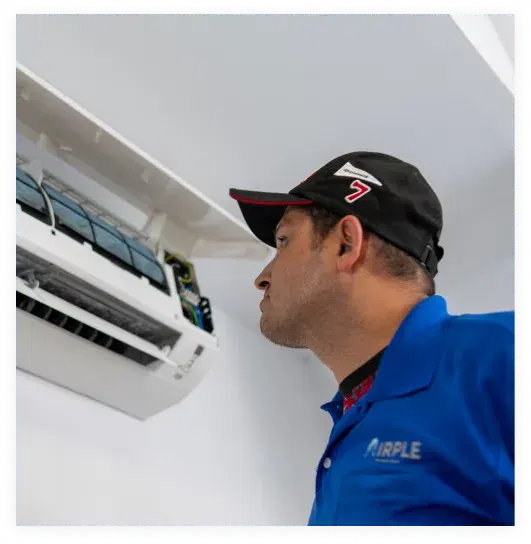

- Expert Technicians: Our team is highly trained in diagnosing and repairing aircon systems.

- Transparent Pricing: We offer clear and upfront pricing, so you know exactly what you’re paying for.

- Comprehensive Services: From pressure testing to repairs, we provide a full range of aircon maintenance services.

- Customer-Centric Approach: We prioritize your comfort and convenience, offering flexible scheduling and prompt service.

Ensure Your Aircon’s Longevity with Airple

A pressure test is a vital step in maintaining your aircon’s performance, especially when leaks are suspected. Don’t wait until a minor issue becomes a major problem. Contact Airple today to schedule your aircon pressure test and experience top-notch service that prioritizes your comfort and convenience.

Book Your Aircon Servicing with Airple Today!

Don't wait until your aircon fails on a sweltering day. Book your aircon servicing with Airple today and experience the comfort of a well-maintained air conditioning system. Our friendly customer service team is ready to assist you with any questions or to schedule your appointment. Trust Airple for all your aircon servicing needs in Singapore.

Looking for the best aircon pressure test service near you? Schedule an appointment today!

Schedule Your Aircon Servicing with Airple Today

Frequently Asked Questions (FAQs)

Why Select

Our Services

At Airple, we are dedicated to providing air conditioning services that upgrade your comfort and satisfaction. As a trusted aircon company in Singapore, we approach every project with precision and care.

Our unwavering standards ensure that your cooling systems perform at their best. From installation to maintenance, our team of expert air conditioning contractors take every step with attention to detail, delivering solutions tailored to your needs.

When you choose Airple as your aircon contractor in Singapore, you can trust us to enhance your comfort with professional and reliable service every time.

Brands of Air Conditioners Supported by AIRPLE